Explore how Aluminum Foundry supports the future of aluminum casting designs

Wiki Article

Checking Out the Numerous Usages and Applications of Aluminum Foundry in Modern Industries

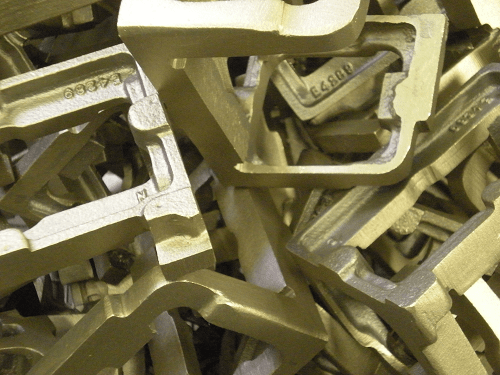

Aluminum shops are integral to a broad variety of contemporary sectors. They generate light-weight and sturdy components that significantly improve effectiveness and performance. From vehicle parts to aerospace structures, the applications are important and varied. As sectors deal with boosting needs for advancement and sustainability, the function of Aluminum factories continues to develop. This comes up with interesting developments and challenges that benefit further expedition.The Duty of Aluminum Foundry in the Automotive Market

As the automobile industry increasingly focuses on weight decrease and fuel efficiency, Aluminum foundries have actually become important contributors to lorry production. These factories produce light-weight Aluminum elements that help manufacturers abide by rigid fuel economy criteria and minimize greenhouse gas emissions. The versatility of Aluminum permits for the development of complex forms and styles, which enhances both capability and aesthetic allure in automobiles.Cast Aluminum parts, such as engine blocks, transmission cases, and wheels, supply significant toughness while preserving a reduced general weight compared to standard materials. Furthermore, Aluminum's resistance to deterioration extends the life-span of automobile parts, driving down maintenance prices for consumers.

As electrical cars gain appeal, Aluminum factories play an important function in producing batteries and architectural components that support the shift to sustainable mobility. Generally, the integration of Aluminum casting in auto manufacturing highlights the product's importance in advancing modern-day car layout and performance.

Aerospace Applications of Aluminum Castings

Light-weight Architectural Parts

The aerospace market progressively depends on light-weight structural components to enhance fuel performance and total efficiency. Aluminum spreadings play an important role in achieving this objective, as they supply a desirable strength-to-weight proportion, making them suitable for different aerospace applications. These components, such as aircraft structures, engine components, and landing gear, add to minimized general weight, which directly converts to decrease fuel consumption and exhausts. Additionally, the toughness and rust resistance of Aluminum guarantee durable efficiency under demanding problems. As makers seek to maximize their styles, Aluminum castings give a flexible solution, making it possible for the development of components that fulfill strict safety and dependability standards. This concentrate on lightweight products is essential for progressing the future of air travel modern technology.Complicated Geometric Designs

Exactly how can complex geometric styles enhance the efficiency and functionality of aerospace elements? In the aerospace industry, complex Aluminum spreadings enable for the development of light-weight yet robust elements, maximizing architectural honesty and aerodynamic efficiency. These styles enable the combination of numerous features, such as cooling down networks and strengthened locations, which traditional manufacturing approaches may not accomplish. By making use of advanced casting strategies, aerospace engineers can create components that adjust precisely to the needed requirements, decreasing product use while taking full advantage of toughness. Additionally, the ability to produce intricate forms reduces the requirement for setting up, simplifying manufacturing processes and enhancing dependability. Generally, intricate geometric layouts play an important function in satisfying the requiring efficiency standards crucial for modern aerospace applications.Corrosion Resistance Residences

In aerospace applications, the performance of elements is substantially affected by their resistance to deterioration. Aluminum spreadings are preferred for their phenomenal deterioration resistance, which is essential for components exposed to harsh environments, such as high-altitude trips and differing climatic problems. The natural oxide layer based on Aluminum surfaces offers a protective barrier that substantially lowers deterioration prices. Furthermore, making use of alloying elements like silicon and magnesium enhances this residential or commercial property, making Aluminum castings particularly ideal for airplane structures and engine components. The light-weight nature of Aluminum, paired with its rust resistance, contributes to improved gas effectiveness and longevity of airplane. These features highlight the vital role of Aluminum Foundry ahead of time aerospace modern technologies and making sure the safety and integrity of air travel systems.

Enhancing Durable Goods With Aluminum Foundry Solutions

Aluminum Foundry solutions substantially improve durable goods by enabling lightweight item styles that boost functionality and transportability. Furthermore, the integral rust resistance of Aluminum lengthens the lifespan of these products, making them more attractive to customers. Affordable production services additionally guarantee that business can supply premium things without compromising on cost.Light-weight Product Style

An expanding variety of durable goods suppliers are turning to Aluminum Foundry services to improve their item designs with light-weight products. By making use of Aluminum, these manufacturers can create things that are not just lighter but also maintain toughness and sturdiness. This shift towards lightweight item layout permits for improved usability and effectiveness, catering to customer needs for mobile and easy-to-handle items. In addition, Aluminum's versatility helps with modern visual appeals and elaborate designs, appealing to consumers who value both functionality and style. The adoption of Aluminum Foundry strategies makes it possible for firms to introduce and separate their offerings in an affordable market, eventually causing boosted client fulfillment and loyalty. This trend highlights the crucial role of material option in modern item advancement techniques.Corrosion Resistance Benefits

While several products are prone to rust, Aluminum stands apart due to its all-natural resistance, making it a suitable option for enhancing durable goods. This innate home of Aluminum allows items to preserve their aesthetic allure and structural honesty gradually, even in challenging settings. As an example, items such as cookware, outdoor furnishings, and vehicle components profit significantly from Aluminum's ability to withstand corrosion. Coatings and treatments can better improve this particular, guaranteeing long life and sturdiness. Consequently, makers can generate reputable, low-maintenance items that meet customer needs for top quality and efficiency. Consequently, Aluminum Foundry remedies play a vital duty in fostering advancement throughout various industries by supplying corrosion-resistant alternatives that elevate the requirement of customer items.Affordable Manufacturing Solutions

Changing the landscape of production, Aluminum Foundry solutions offer an economical strategy to producing top quality customer products. These approaches make it possible for suppliers to develop intricate designs while reducing material waste, thus minimizing general manufacturing prices. The light-weight nature of Aluminum boosts the performance of transport and handling, more lowering expenditures. In addition, the longevity of Aluminum warranties that ended up items keep their honesty gradually, minimizing the requirement for regular replacements. Industries ranging from automotive to electronics profit from the convenience of Aluminum Foundry procedures, permitting ingenious styles that meet consumer needs without endangering on quality. By leveraging these services, manufacturers can remain affordable in an ever-evolving market, eventually enhancing product allure and customer complete satisfaction.Aluminum Foundry Innovations in Construction

As the building and construction market seeks to boost effectiveness and sustainability, developments in Aluminum Foundry applications are coming to be progressively significant. The light-weight nature of Aluminum, integrated with its toughness and rust resistance, is transforming standard construction approaches. Advanced casting strategies permit the creation of complicated shapes and styles that were previously unattainable. This not only reduces material waste but likewise lowers transportation prices because of the lighter weight of frameworks.

Furthermore, the assimilation of Aluminum components in modular building and construction is acquiring grip. Upreared Aluminum components improve setting up processes on-site, leading to much shorter job timelines. Furthermore, the recyclability of Aluminum sustains sustainable building techniques, aligning with worldwide objectives for reduced environmental effect.

Technologies such as 3D printing of Aluminum and enhanced alloys even more broaden the material's applications, providing engineers and engineers with higher versatility in layout and functionality. Generally, these innovations setting Aluminum Foundry procedures as pivotal in modern building.

Aluminum Foundry

The Effect of Aluminum Casting on Electronic Devices Production

Aluminum spreading plays an essential duty in electronics producing, particularly due to its beneficial buildings such as thermal conductivity and light-weight nature. These attributes make Aluminum an excellent option for numerous digital elements, including warm sinks, rooms, and structural parts. The ability to efficiently dissipate heat is essential in digital tools, as it assists preserve optimal performance and lengthens component lifespan.Moreover, Aluminum's light-weight nature adds to the general reduction in device weight, which is increasingly vital in mobile electronics. The casting procedure enables for accurate dimensions and detailed styles, helping with the manufacturing of complicated shapes that fulfill the strict requirements of modern-day innovation.

Additionally, Aluminum's deterioration resistance improves the resilience of digital products, making them ideal for diverse settings. On the whole, Aluminum casting substantially enhances the efficiency, efficiency, and long life of electronic tools, strengthening its relevance in the ever-evolving electronic devices manufacturing landscape.

Lasting Practices in Aluminum Foundry Procedures

Carrying out lasting methods in Aluminum Foundry procedures is becoming increasingly important as markets look for to reduce their ecological impact. Factories are adopting energy-efficient innovations, such as innovative melting and casting procedures that decrease power consumption. Furthermore, making use of recycled Aluminum significantly reduces the carbon impact related to main Aluminum production.Water preservation approaches are also essential, with numerous factories applying closed-loop water systems to reduce waste and improve efficiency. Even more, the fostering of environmentally friendly materials and finishes reduces hazardous discharges throughout casting.

Waste monitoring methods, including the recycling of scrap metal and the correct disposal of harmful materials, are necessary to making certain a lasting procedure. By incorporating these methods, Aluminum factories can not just conform with environmental policies however likewise improve their competition in a market progressively concentrated on sustainability (Aluminum Foundry). These efforts demonstrate a commitment to both ecological stewardship and functional effectiveness

Future Patterns in Aluminum Foundry Technology

While the Aluminum Foundry industry continues to advance, numerous crucial patterns are emerging that promise to improve its future. One considerable pattern is the increasing fostering of innovative automation and robotics, which improve efficiency and accuracy in casting procedures. This shift allows shops to minimize labor costs while boosting manufacturing quality. In enhancement, the assimilation of man-made intelligence and artificial intelligence is anticipated to optimize procedures by anticipating upkeep requirements and enhancing process.Another vital pattern is the focus on sustainability, with factories increasingly taking on environment-friendly methods, such as recycling Aluminum scrap and using renewable power sources. The growth of lightweight Aluminum alloys is gaining grip, specifically in the aerospace and auto sectors, where weight decrease is important for efficiency and gas efficiency. As the market welcomes these developments, the Aluminum Foundry market is positioned for a more lasting and innovative future.

Often Asked Concerns

What Are the Environmental Influences of Aluminum Foundry Operations?

The ecological effects of Aluminum Foundry procedures consist of air contamination from exhausts, water contamination from runoff, and energy intake. These factors contribute to environmental deterioration and posture wellness risks to surrounding communities and neighborhoods.Just How Does Aluminum Spreading Contrast to Various Other Steel Spreading Approaches?

Aluminum casting deals benefits such as reduced weight and rust resistance compared to other methods like steel or iron casting. Additionally, it allows for intricate designs, enhancing capability while reducing product waste in making processes.What Precaution Are Implemented in Aluminum Foundries?

Precaution in Aluminum shops consist of personal protective equipment, proper air flow, fire safety and security protocols, normal tools upkeep, employee training on risks, and adherence to regulatory criteria to decrease dangers connected with heats and liquified steel.What Is the Cost-Effectiveness of Aluminum Foundry Solutions?

The cost-effectiveness of Aluminum Foundry remedies is considerable, as they provide lightweight products, minimized energy intake, and reduced production prices. These aspects add to boosted efficiency and success in numerous making fields.Just How Can Tiny Businesses Utilize Aluminum Foundry Services?

Small companies can utilize Aluminum Foundry solutions by outsourcing manufacturing for customized parts, minimizing manufacturing expenses, and leveraging lower volume needs. This enables them to introduce quickly and complete efficiently without hefty preliminary financial investments in equipment.As the auto industry significantly prioritizes weight decrease and gas performance, Aluminum foundries have actually arised as important factors to vehicle production. Aluminum Foundry solutions substantially enhance customer products by making it possible for lightweight product layouts that improve functionality and transportability. A growing number of consumer products suppliers are turning to Aluminum Foundry options to boost their product styles via light-weight materials. As the building sector looks for to enhance performance and sustainability, developments in Aluminum Foundry applications are becoming progressively significant. By incorporating these techniques, Aluminum shops can not only comply with environmental guidelines but also enhance their competitiveness in a market significantly concentrated on sustainability.

Report this wiki page